In the competitive realm of automotive manufacturing, the longevity and performance of tires play a crucial role in ensuring vehicle safety and reliability. One of the key factors influencing tire quality is the use of rubber aging-resistant materials. These materials not only extend the life of the tires, but also enhance their performance on the road.

Rubber aging resistance is vital in maintaining tire durability, especially under various environmental conditions. Aging-resistant materials help to reduce degradation caused by factors such as UV light, ozone, and heat. This degradation can lead to reduced performance, increased wear, and ultimately, tire failure.

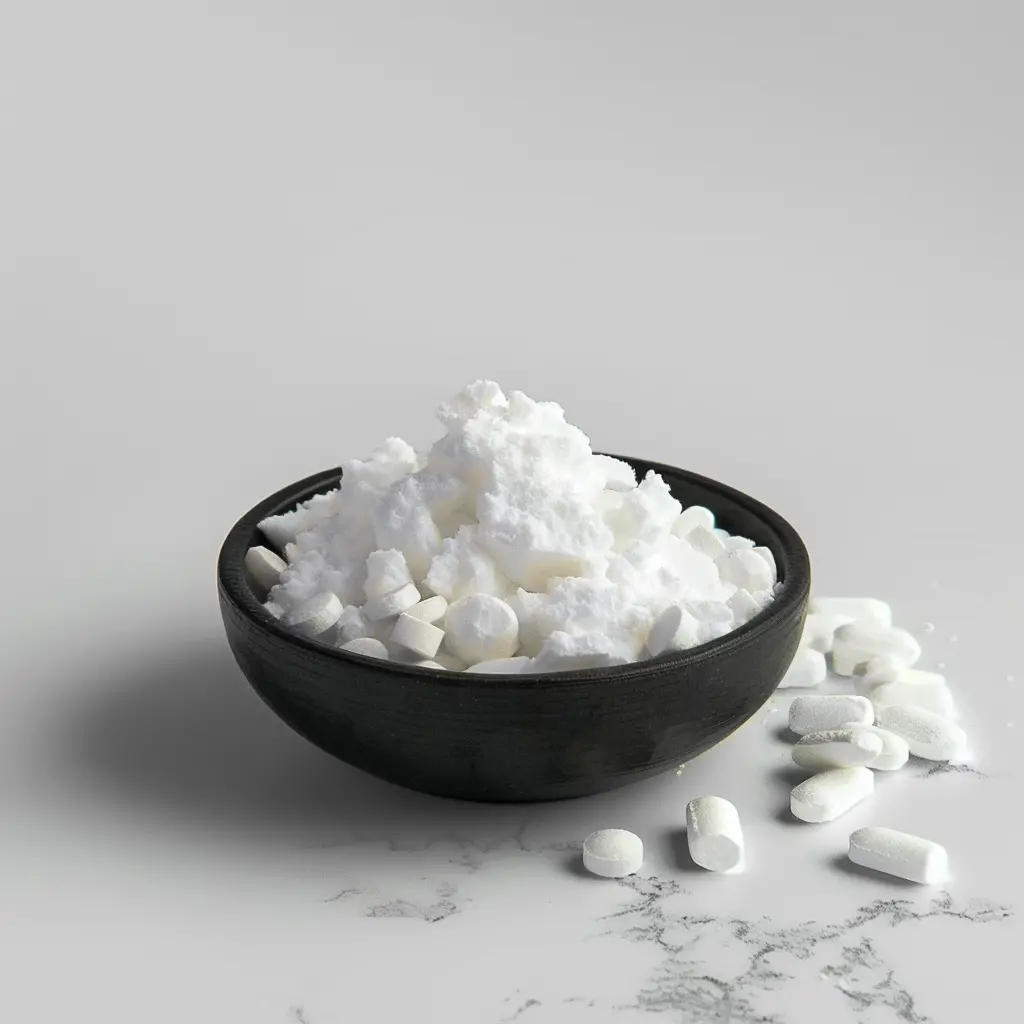

Several additives are commonly used in the formulation of aging-resistant rubber. For instance, the inclusion of Diphenylamine (DPA) serves to provide antioxidant properties, reducing oxidative degradation and enhancing the overall stability of the tire material.

.jpg)

Other key materials such as Preservative CTP (PVI) and Rubber antidegradant MB (MBI) are also used to ensure maximum durability and performance throughout the tire’s lifespan. These materials work synergistically to combat the effects of aging, ensuring that the tires maintain their physical properties and functionality.

In conclusion, the integration of rubber aging-resistant materials is essential in the tire manufacturing process. By utilizing advanced formulations that include various aging-resistant additives, manufacturers can enhance tire durability and performance, ultimately delivering safer and more reliable products to consumers.

Investing in aging-resistant materials not only benefits the end-user but also fortifies the manufacturer's reputation in a competitive market. As the automotive industry continues to evolve, the demand for high-performance tires that withstand the test of time will remain a paramount focus.