The rubber industry has seen significant advancements in recent years, particularly with the introduction of high-efficiency sulfur accelerators like DCBS. This article delves into the applications of DCBS and its impact on the industry.

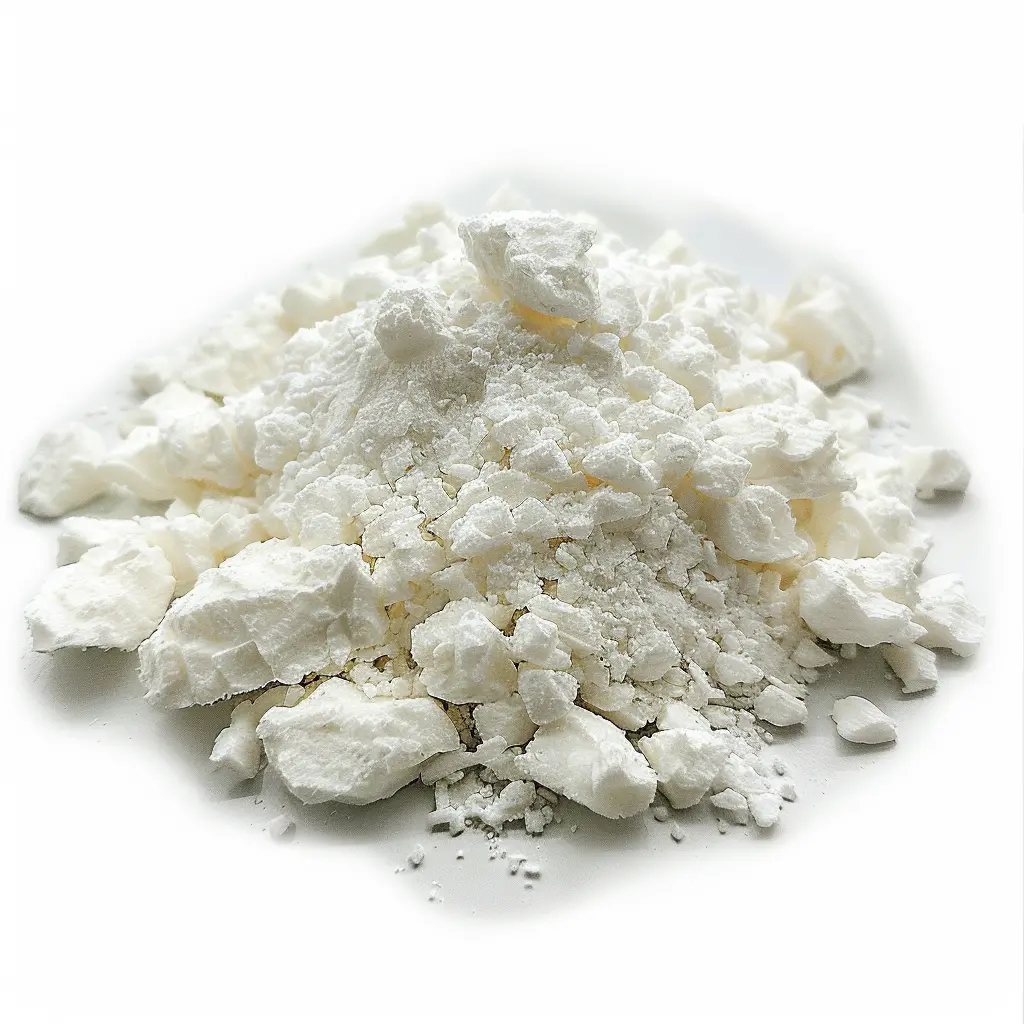

DCBS, or N-1, 3-dimethylbutyl-N-phenylthiourea, is increasingly utilized in the vulcanization process of rubber. Its effectiveness in enhancing the properties of rubber products has led to its widespread adoption in various applications, including:

.jpg)

As the demand for high-performance rubber products continues to rise, the market for DCBS sulfur accelerators is projected to grow exponentially. Key trends influencing this market include:

DCBS sulfur accelerators are paving the way for a new era in rubber manufacturing, characterized by improved performance and sustainability. Industry stakeholders should remain informed about these developments to leverage the advantages that DCBS brings to the market.

In conclusion, the exploration of DCBS sulfur accelerators reveals a promising future for the rubber industry, which is embracing innovation and sustainability.