The rubber industry plays a pivotal role in various sectors, from automotive to consumer goods. However, one of the most pressing challenges it faces is the impact of high temperature environments on rubber products. In this article, we will explore the strategies and innovations that the rubber industry is employing to adapt to these challenges, ensuring enhanced durability, sustainability, and performance.

High temperatures can lead to accelerated degradation of rubber, affecting its physical properties and lifespan. Factors such as thermal aging, oxidation, and loss of flexibility are critical concerns for manufacturers. As temperatures continue to rise globally due to climate change, understanding these impacts is essential for the rubber industry's survival and growth.

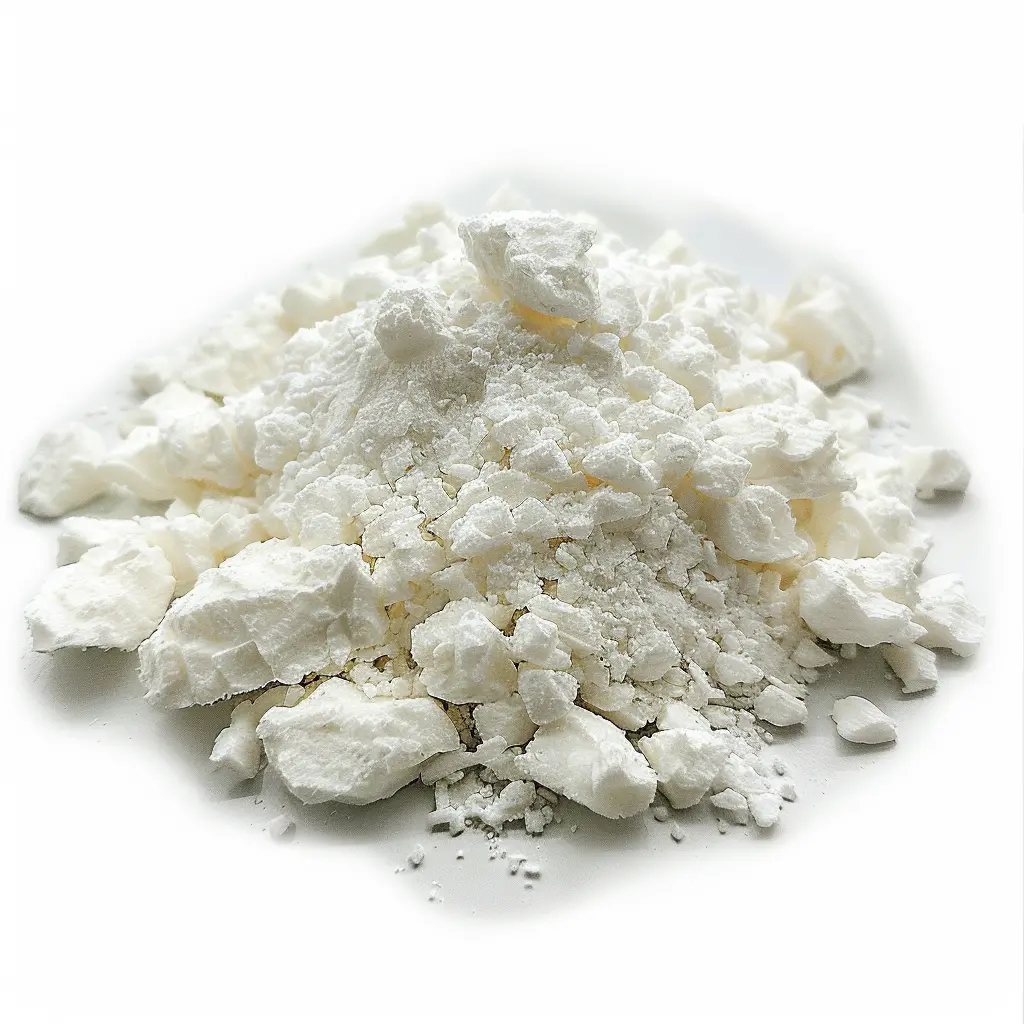

To combat high temperature challenges, manufacturers are investing in innovative formulations of rubber materials. For instance, incorporating specialized additives such as Diphenylamine (DPA) greatly enhances the heat resistance of rubber, providing longer longevity and reliability in extreme conditions.

Sustainability has become a focal point in the rubber industry. Companies are now turning to environmentally friendly practices, such as integrating natural rubber and introducing Rubber Penetrant DBD agents that not only improve product performance but also reduce ecological impacts. These innovations are vital for meeting the increasing consumer demand for sustainable products.

The rubber industry continues to rise to the challenge posed by high temperature environments. Through innovative formulations and sustainable practices, manufacturers are ensuring that rubber products not only perform well but also align with modern demands for sustainability. As the industry evolves, ongoing research and development will be key to overcoming future obstacles.

.jpg)