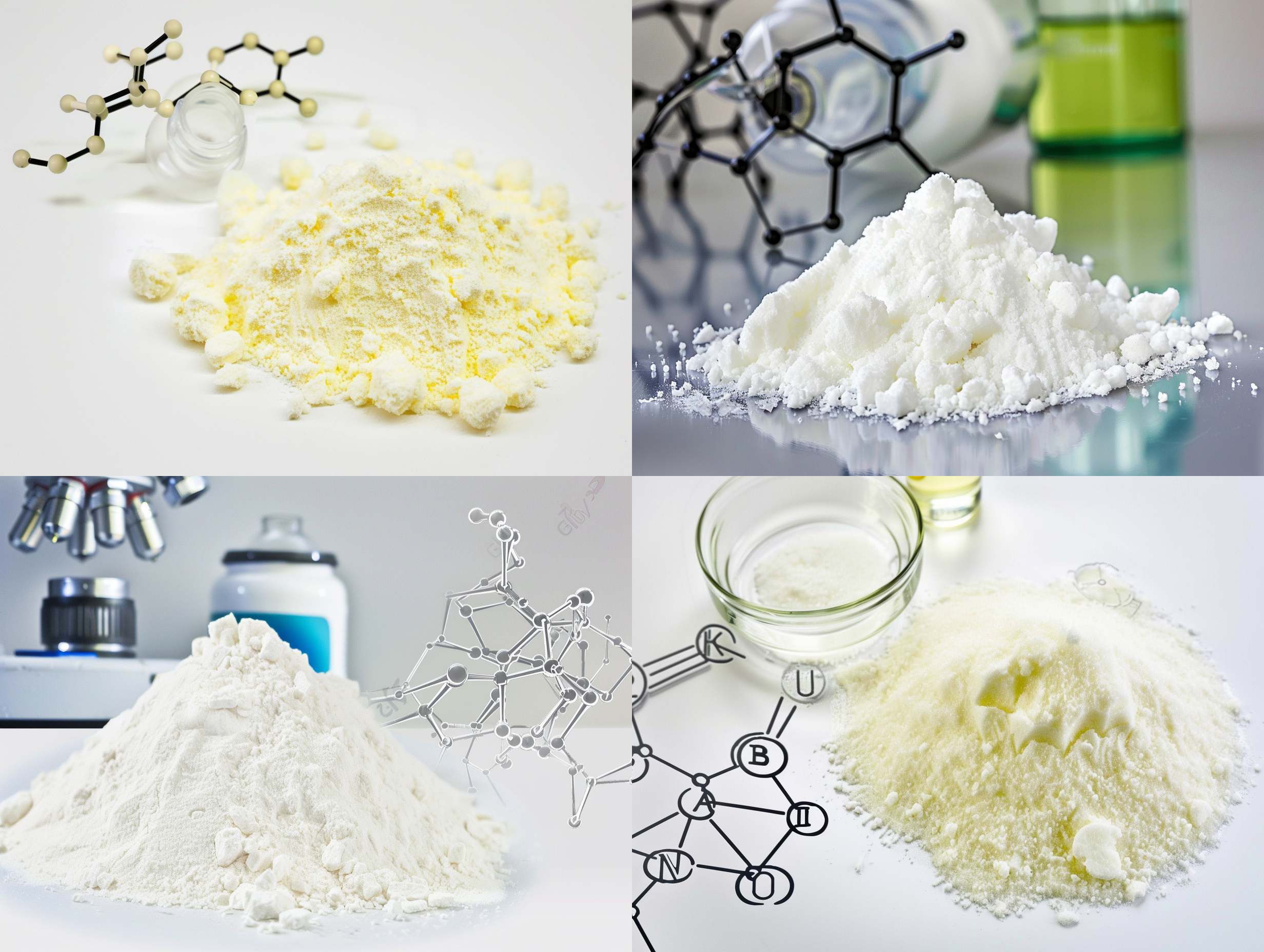

Rubber Accelerator MBT(M) is a crucial additive in the rubber manufacturing process, enhancing the efficiency and performance of rubber products. This guide provides essential tips for the effective storage and utilization of MBT(M) to ensure safety and compliance while maximizing performance.

1. Temperature Control: Store MBT(M) in a cool, dry place, away from direct sunlight and heat sources. Optimal storage temperature is between 15°C to 25°C.

2. Container Requirements: Keep the product in its original packaging, tightly sealed to prevent moisture absorption. Use containers specifically labeled for chemical storage.

1. Dosage: Follow the manufacturer’s guidelines for optimal dosage per batch to achieve desired vulcanization results.

2. Safety Measures: Always wear appropriate personal protective equipment (PPE) such as gloves and goggles when handling the product. Ensure proper ventilation in the working area.

Regularly check for updates on regulatory compliance to ensure all safety standards are met. Proper training for personnel handling MBT(M) is essential.

.jpg)

Employing proper storage and usage practices for Rubber Accelerator MBT(M) is essential for maximizing its effectiveness while ensuring safety and compliance. For further details, contact your supplier or refer to the product’s safety data sheet (SDS).